We are fueled by passion

Our Values & Mission

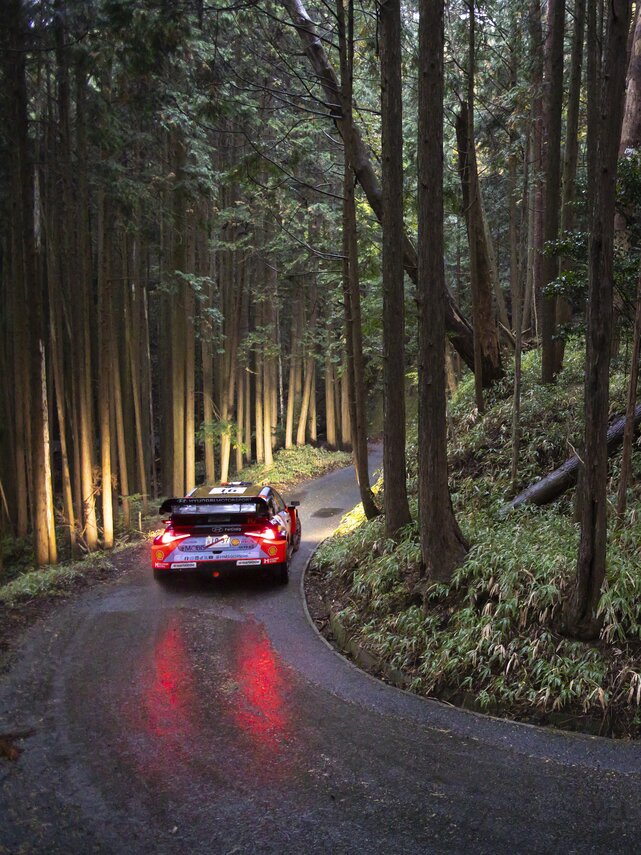

Established on 19 December 2012, Hyundai Motorsport GmbH (HMSG) is responsible for Hyundai Motor Group’s global motorsport activities. Our portfolio of series features flagship participation in the FIA World Rally Championship (WRC). In addition, the company’s Customer Racing activities, which include the i20 N Rally2 and Elantra N TCR projects, have helped enhance Hyundai’s high-performance image to consumers around the world. Our commitment to high speed and performance will be taken even further with the start of the endurance racing program in 2026.

Our mission is to drive innovation, engineering excellence and brand passion through world-class motorsport competition. We strive to build our expertise and share knowledge across different disciplines in motorsport, fostering the talent of our team.

WRC Manufacturers' titles

2

WRC Drivers' & Co-Drivers' title

1

TCR World Tour Teams' title

1

TCR World Drivers' titles

2

FIA WTCR Teams' title

1

FIA WTCR Drivers' titles

3

Customer Racing titles

120+

Hyundai Motorsport

President

Cyril Abiteboul

View profile

Technical Director

François-Xavier Demaison

View profile

Operations Director

Sébastien Metz

Head of Powertrain

Julien Moncet

View profile

Head of Chassis Engineering

Massimo Carriero

Customer Racing Manager

Benoit Nogier

View profile

Hyundai Shell Mobis WRT

Our History

2026

2026

Genesis Magma Racing enters its first season of the FIA World Endurance Championship, targeting consistency and reliability, while experienced drivers rejoin the Hyundai Motorsport line-up in WRC in search of further wins and titles.

2025

2025

Hyundai Motorsport teams in WRC and TCR World Tour claimed victories in a tough year, while Genesis Magma Racing engineers were hard at work bringing the GMR-001 Hypercar to life.

2024

2024

Thierry Neuville and Martijn Wydaeghe became Hyundai Motorsport's first WRC Drivers’ and Co-Drivers’ champions after a dramatic season finale in Japan. In TCR World Tour, Norbert Michelisz lifted his second consecutive Drivers’ title. 2024 also marked the fourth consecutive title in the TCR class for the Elantra N TCR at the Nürburgring 24 Hours.

To pursue new challenges, Hyundai Motorsport announced its plan to enter the pinnacle of endurance racing under the Genesis Magma Racing banner: WEC in 2026 and IMSA in 2027.

2023

2023

HMSG's customers saw global success throughout 2023, securing championships in rally and racing series. Most notably, the Elantra N TCR took top honours in the inaugural TCR World Tour season with Norbert Michelisz, as he secured the Drivers’ title.

2022

2022

2022 marked the beginning of the hybrid era in WRC and the debut season of our i20 N Rally1 Hybrid, resulting in the greatest single-year win tally in the series for the team. As ETCR entered its second year, the Veloster N ETCR battled hard against the competition and once again claimed second in the Manufacturers’ championship.

2021

2021

HMSG made its electric racing debut in PURE ETCR with the Veloster N ETCR. In a closely-fought battle, the drivers’ crown was narrowly missed out by a single point. Meanwhile, the Customer Racing department presented new additions to its fleet, as the Elantra N TCR and i20 N Rally2 joined our already established challengers: the i30 N TCR, Veloster N TCR and i20 R5.

2020

2020

Building on the momentum from the previous season, Hyundai Motorsport claimed its second consecutive WRC Manufacturers’ title in 2020, further solidifying its position as a top-tier rally team.

2019

2019

A momentous year for the company was capped with an inaugural WRC Manufacturers’ Championship title and the FIA WTCR Drivers’ title secured by Norbert Michelisz with the i30 N TCR, making it a landmark year for HMSG in both rally and touring car disciplines.

2018

2018

The success of the Customer Racing Department continued when the inaugural season of FIA WTCR drivers' championship brought the triumph of Gabriele Tarquini and the i30 N TCR.

2017

2017

The dawn of the i30 N TCR project took Hyundai Motorsport into the world of circuit racing for the first time, heralding an exciting new chapter for the team.

2016

2016

Hyundai Motorsport debuted the New Generation i20 WRC, the first car developed with full capabilities of the company, and the i20 R5 made its first rally starts in customers' hands.

2015

2015

In 2015, Hyundai Motorsport established a brand new Customer Racing department to provide high-perfoming cars to private teams and drivers all over the world. This marked the beginning of HMSG's involvement in circuit racing.

2014

2014

After an intensive development phase, Hyundai Motorsport made its official debut in the FIA World Rally Championship (WRC) in 2014 with the Hyundai i20 WRC. Under the leadership of experienced motorsport professionals, the team quickly demonstrated its competitiveness, securing its first victory at Rallye Deutschland in the same year.

2013

2013

Hyundai Motorsport focused on the development of a brand new car, the Hyundai i20 WRC for WRC stages, while forming the team that was to be responsible for running the car in the championship.

2012

2012

In December 2012, Hyundai Motorsport (HMSG) opened the door of its facility, in Alzenau (Frankfurt, Germany). The company was established to lead Hyundai's global motorsport activities and showcase the brand’s technical expertise. The company's initial and primary focus was its return to the FIA World Rally Championship (WRC)—a series in which Hyundai had previously competed from 2000 to 2003.